Where w mass of the casting kg. Economic and maximizing casting yield.

Pdf Automation Of Gating System Parameters For Green Sand Iron Castings

The side riser is a live riser receiving the last hot metal to enter the mold.

. If the liquid metal is poured very slowly then the time taken to fill up the mould is rather. 280 Bronze Tin 190 Brass 180 gating Bottom 130 gating Top by given constant a is K s W K t time Pouring 2 3 2 6 Intricately shaped thin walled castings with Grey CI mass casting with gates and risers kg K 3 a constant as given below 7 For casting above 450 kg and upto 1000 kg where K 4 a constant as given below s W K t time. View Gating System Design Optimization for Sand Castingpdf from ME 367 at Çukurova University.

Pouring conditions and gating system design affect the air entrainment and hence the extent of oxide inclusion for-mation. Full PDF Package Download Full PDF Package. Some declare that it demands a number of talent on portray your own private nails.

DESIGN OF DOWN-RUNNER OR SPRUE 21 Calculate the weight of liquid metal to be poured includes the casting the feeder and all elements of gating system 22 Choose location and design of gating system. 21 Casting Defects in. There are several objectives to efficient gating design.

For sound casting we need to optimize the gating system for a given geometry of casting. 3 Gating Design Difficulties faced in pouring and explain how these can be overcome by using an appropriate gating design A good gating system ensures distribution of the metal in the mould cavity at a proper rate without excessive temperature loss turbulence and entrapping gases and slags. Pouring basin or.

Chapter 5 Gating System Design for a Multi-Cavity Die-Casting Die The gating system is a channel or a passage in the die through which the molten metal reaches the cavities. 26 Full PDFs related to this paper. Gatingriser system design is optimized to improve casting quality.

Compared with the initial design it is found that the optimized casting design can decrease porosity around. Mainly depend on gating system. Liquid metal impingement inside sprues breaking waves in runners falling jets inside of the mold cavity and rising vertical jets or fountains formed.

1 Department of Mechanical Engineering Lagos State University Epe. If the gating system is designed incorrectly the following errors can occur. In Casting design the gating riser system design has a direct influence on quality of cast component.

Risers and Riser Design Riser must be separated from the casting upon completion so the connection area must be as small as possible Figure 11-13 Schematic of a sand casting mold showing a an open-type top riser and b a blind-type side riser. Up to 24 cash back Gating system design is crucial in controlling the rate and turbulence in the molten metal being poured the flow of liquid metal through the castings system and the temperature gradient within the metalcasting. Gating design in casting pdf As being a starter you can make your own personal Nail Artwork Effect employing two techniques.

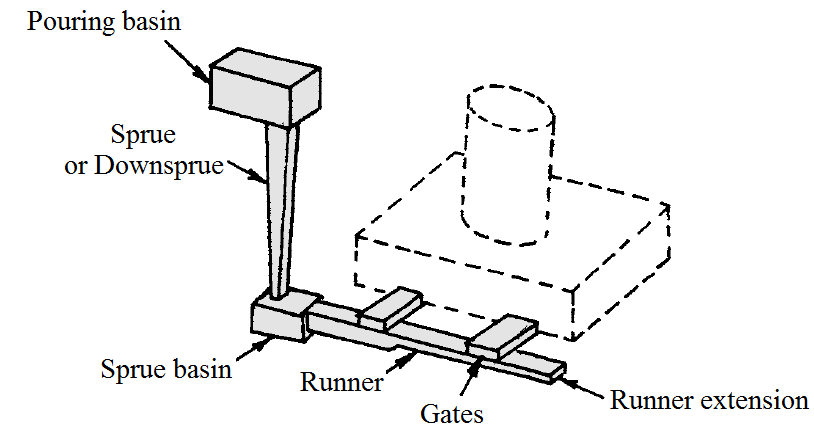

Most engineering problems casting designs done trial and error basis. The gating system in sand casting includes. The riser and gating system in casting process is shown in Figure 8.

Pdf Design Of Gating And Riser System For Grate Bar Casting For sound casting we need to optimize the gating system for a given geometry of casting. CONTENTS vii 128 Startup and Mold Manufacturing Cost. Pouring bushbasin for larger casting 2.

And contain little explanation on the alloy A-356. Examples of air entraining flows in casting gating systems include. Gating System Design Optimization for Sand Casting Dolar Vaghasia 07310032.

The present rules can be used to develop the first trial riser design. Gating System Design Optimization for Sand Casting MTech Dissertation Submitted in. Due to the existing Flat gate system in the existing model the following defects occur in the casting leading to rejection and loss in quality.

Critical MES high-tech die casting can produce rigid components with ultrathin walls. Make metal penetrate the mold wall. 23 Determinedecide on total filling time of casting.

Basic gating design for gravity-fed vertically-parted permanent mold castings has changed little in recent decades. Availability of modern software tool give designer an insight into the detail of fluid flow heat transfer. Causing shrinkage of objects in the mold.

Short-length connections are most desirable. Obtaining 3D decorations produced from plastic and glue them on the nail or you can find your own private acrylic and paint your own nails. Software can be used in place of actual casting trials to detect feeding and risering problems in a steel casting the present rules still serve several important purposes.

A short summary of this paper. Pouring time- The time for complete filling of mould termed as pouring time. In the thesis one engine block is used to verify the effectiveness of the optimization method.

Directional solidification in order to achieve sound casting. Gating Design In Casting Pdf. Hence a new optimized gate design is necessary in order to remove defects from the casting.

Defects may arise in the casting that are direct results of poor gating practices implemented by blindly following gating guidelines. Gating System Design Solutions for Casting De fects from Pouring. Riser for sand casting process 361 Design Requirements of Risers 1.

Gating System Design Optimization for Sand Casting Dolar Vaghasia 07310032. Hence a good gating system will create directional solidification throughout the casting since the flow of. Another major element is filter or slag trap which usually placed in runner or between runner and ingate to filter slag and other inclusions.

See Appendix 1 and Appendix 2. The riser and gating system in casting process is shown in Figure 8. For steel casting Pouring time t 24335 - 03953 log ww sec.

This report explains how to do the necessary gating design calculation for the casting of the desired dimension. The gating system design refers to the design of its various elements such as gate runner overflow and biscuit which are described later in Section 51. As a result the designer has much more latitude with die casting than with plastics powdered metals or stampings to design relatively thick walls for strength in some areas and very thin walls for conserving material in others.

The literature available on gating design optimization recommends maximizing yield minimizing ingate velocity of molten metal optimizing the ingate location and minimizing the warpage. By gaining a better understanding of these methods and practices improvements in casting yields and integrity should be realized. 139 129 Personnel Cost.

24 Gating design Calculations. Casting simulation does not provide the initial riser design for a casting. Gatingriser system design is critical to improving casting quality.

Pdf Optimized Design Of Gating Riser System In Casting Based On Cad And Simulation Technology Semantic Scholar

Types Of Gating System In Casting Process Bajrang Engineering

Pdf Design Of Gating And Riser System For Grate Bar Casting

Gating System Design Pdfcoffee Com

Pdf Gating Design Criteria For Sound Casting Semantic Scholar

Pdf Gating System Design And Material Analysis For The Sand Casting Of A Sprocket

Pdf Gating System Design For Casting Thin Aluminium Alloy Al Si Plates Semantic Scholar

0 comments

Post a Comment